|

Ningbo Vichnet Communication Science & Technology Ltd.

|

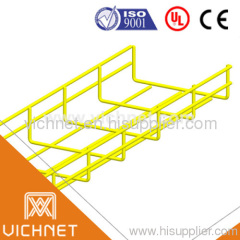

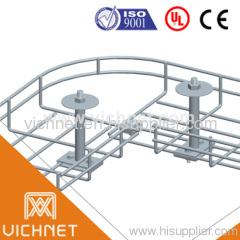

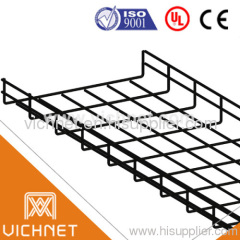

cable cage trays

| Price: | 5.0~50.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. No1 wire mesh cable tray manufactory in China

2. ISO9001:2008,GMC qualified

3. SGS test passed

4.Excellent loading capacity

Brief Introduction of Cable Tray Systems:

A cable tray system, according to the US National Electrical Code, is "a unit or assembly of units or sections and associated fittings forming a rigid structural system used to securely fasten or support cables and raceways." Cable trays are used to hold up and distribute cables.

A cable tray system, according to the US National Electrical Code, is "a unit or assembly of units or sections and associated fittings forming a rigid structural system used to securely fasten or support cables and raceways." Cable trays are used to hold up and distribute cables.

With features of light weight, low cost, special shape, easy for installation, good ventilation etc, Ladder type cable trays suit for laying of large diameter cable, especially suitable for high/low voltage power cable laying. Ladder trays are used in applications with intermediate to long support spans

Cable ladders are widely used as temporary usage of electric power in building site, industry and mining enterprise, decoration and mending where adopt the electric power of 220V and 380V.

Features and Benefits of Ladder Cable Trays:

1. Requires NO bending or cutting

2. Acts as a continuous ground conductor; no grounding splices

3. Adapts to difficult architectural designs, accommodates changes in direction and elevation of cable runs

4. Cuts installation time up to 50 percent.

5. Provides strength, rigidity without additional hardware.

6. Has smooth edges to avoid any cut in both the wire and the installer.

7. Galvanized, powder coated or hot dip galvanized finishes to minimize corrosion.

8. All support hardware available.

9. Custom sizes and materials available.

Features and Benefits of Ladder Cable Trays:

1. Requires NO bending or cutting

2. Acts as a continuous ground conductor; no grounding splices

3. Adapts to difficult architectural designs, accommodates changes in direction and elevation of cable runs

4. Cuts installation time up to 50 percent.

5. Provides strength, rigidity without additional hardware.

6. Has smooth edges to avoid any cut in both the wire and the installer.

7. Galvanized, powder coated or hot dip galvanized finishes to minimize corrosion.

8. All support hardware available.

9. Custom sizes and materials available.

Design of Ladder Cable Trays:

Two longitudinal side rails connected by individual O-Rung/U-Channel spaced on 150, 225, 300 or 600 mm centers. Cable Ladders are the most commonly used type of trays for maximum ventilation. Available in all materials.

Two longitudinal side rails connected by individual O-Rung/U-Channel spaced on 150, 225, 300 or 600 mm centers. Cable Ladders are the most commonly used type of trays for maximum ventilation. Available in all materials.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

.jpg)

.jpg)

.jpg)

.jpg)