|

Ningbo Vichnet Communication Science & Technology Ltd.

|

mesh cable

| Price: | 5.0~50.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1\Simple for Maintenance and Repair Work/2\Flexible/3\Decrease cable purchase cost and decrease power consumption4\Good looking5\Excellent Bearing Abi

mesh type cable tray

Comparing with traditional cable tray, SLS mesh type cable tray has the following advantages:

Comparing with traditional cable tray, SLS mesh type cable tray has the following advantages:

1\Simple for Maintenance and Repair Work

Since equipments in machine room will be increased, dismantled or modified from time to time, and meanwhile cables will be changed accordingly, in such case the mesh type cable tray can make the cables easy to be seen; so the to be changed cables can be easily observed and make the maintenance and repair works simple.

Since equipments in machine room will be increased, dismantled or modified from time to time, and meanwhile cables will be changed accordingly, in such case the mesh type cable tray can make the cables easy to be seen; so the to be changed cables can be easily observed and make the maintenance and repair works simple.

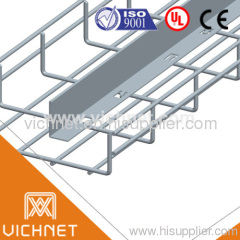

2\Flexible

Mesh type cable tray do no need to equipped with any elbow or T parts, and can be made to any style according to construction requirement. This advantage can make easier the work of designer and erection worker and can greatly short the installation time.

Mesh type cable tray do no need to equipped with any elbow or T parts, and can be made to any style according to construction requirement. This advantage can make easier the work of designer and erection worker and can greatly short the installation time.

3\Decrease cable purchase cost and decrease power consumption

Mesh type cable tray is open style which will have good ventilation and the heat will not gather so the temperature inside cable tray will not be increased. Accordingly the cable function will be optimized which means small diameter cable can replace the bigger one and decrease cable purchase cost.

Mesh type cable tray is open style which will have good ventilation and the heat will not gather so the temperature inside cable tray will not be increased. Accordingly the cable function will be optimized which means small diameter cable can replace the bigger one and decrease cable purchase cost.

4\Good looking

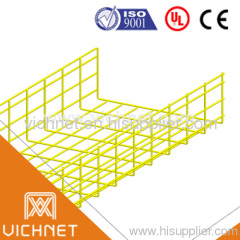

Since cables can be seen and should be lay out in certain order, and mesh type cable tray are fine fabricated and can also be painted as client required, so the entire cable tray system can be good looking which also change the black or grey style. Another popular method is to use the unpainted cable tray but use colorful cables; it will look good after installation since cable tray is open style.

Since cables can be seen and should be lay out in certain order, and mesh type cable tray are fine fabricated and can also be painted as client required, so the entire cable tray system can be good looking which also change the black or grey style. Another popular method is to use the unpainted cable tray but use colorful cables; it will look good after installation since cable tray is open style.

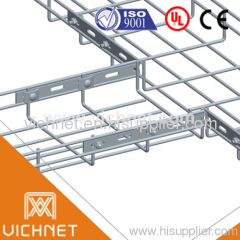

5\Excellent Bearing Ability

Although mesh type cable tray is light but it still good at bearing function. This type of cable tray is made of 4mm-6mm diameter high quality steel wire and is weld by special welding machine crossing and also welding in T type on side and on top, so that each welding point can bear 500 kg tension. T type welding formed safe T edge is the global patent of mesh type cable tray, which avoids the sharp surface of welding point and can not only protect cables but also protect workers.

Although mesh type cable tray is light but it still good at bearing function. This type of cable tray is made of 4mm-6mm diameter high quality steel wire and is weld by special welding machine crossing and also welding in T type on side and on top, so that each welding point can bear 500 kg tension. T type welding formed safe T edge is the global patent of mesh type cable tray, which avoids the sharp surface of welding point and can not only protect cables but also protect workers.

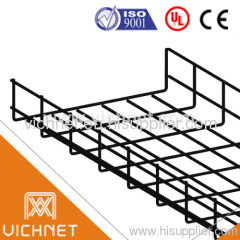

6\Durable

There are lots of surface treatments can be chose for mesh type cable tray. Thickness for galvanization coating is 12-18 μm, the thickness of hot galvanized coating is 60-80 μm; the coating is even and good at anti-corrosion. For some special environment, mesh type cable tray can be made of 304L or 316L high quality stainless steel cable tray and relevant parts, so as to make sure the durability of products.

There are lots of surface treatments can be chose for mesh type cable tray. Thickness for galvanization coating is 12-18 μm, the thickness of hot galvanized coating is 60-80 μm; the coating is even and good at anti-corrosion. For some special environment, mesh type cable tray can be made of 304L or 316L high quality stainless steel cable tray and relevant parts, so as to make sure the durability of products.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)